customized solution?

There is a solution for every pipe system problem: US HERE

Custom-made Solutions

Innovations are not simply created by chance: In most cases, they are the answer to the specific challenges that customers have faced. From the first 3D-CAD models to the development of new process techniques to the mass production of the new solution, everything is possible with KURO. Because every step of value creation is in our hands, we can influence production individually at each point.

Manufacturing and finishing processes

Our solution for your need

Our experts will be happy to take your individual inquiry in the first step by phone, e-mail or contact form.

In a joint discussion, we clarify the requirements for your product and explain our range of services. We go into detail about all relevant topics and design the next steps together with you.

In addition to an informative offer, we individually design a 2D/3D drawing or additionally a sample for acceptance.

With innovative production processes and self-developed manufacturing methods, we manufacture products according to your individual requirements. From one-off production to series production or as contract manufacturing with the customer's own material, your product will be manufactured precisely and with high quality.

A warehouse area of 10,000 sqm offers the possibility to optimally store blanks and finished products. Excellent logistics and packaging solutions enable delivery individually according to customer requirements.

From the idea to innovation.

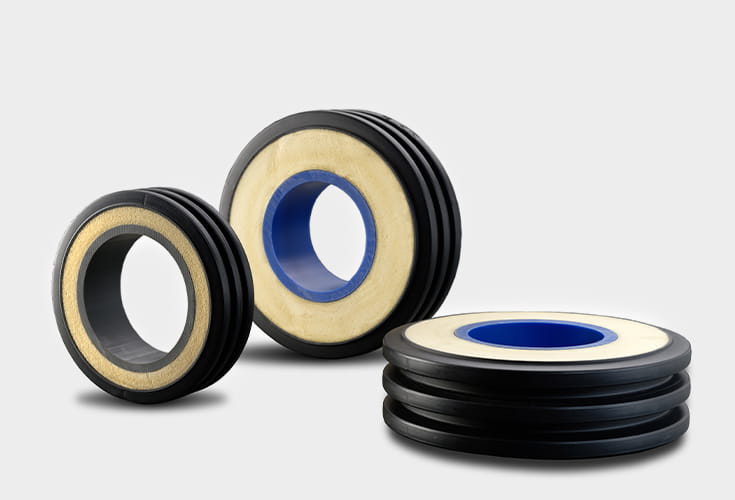

Some concrete examples being the result of customer's request that have already resulted in specific products.

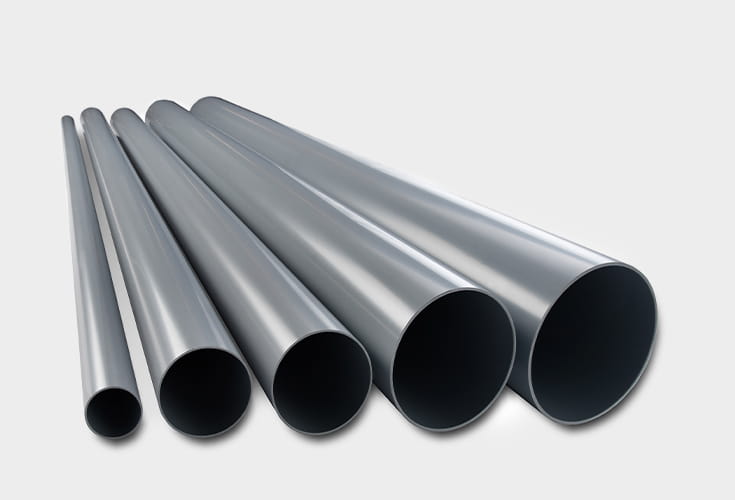

CNC-treated tubes / Milling parts

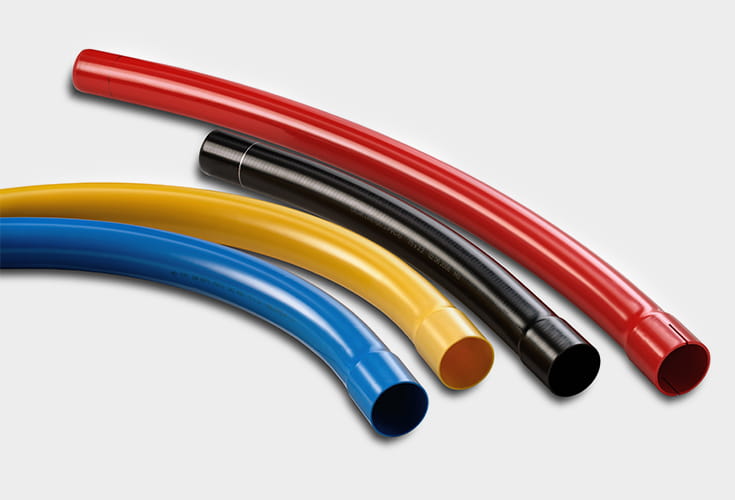

Pipes made to measure - Individual colours and dimensionsn

CLEAN TUBE The antibacterial pneumatic tube

Pre-insulated pipes and pipe bends

Bends for Utility entry point sets

FOODPIPE - The food-safe pipe made of PVC-U

Customised sheets - individual colours and dimensions

Special solutions - bonded or welded

Contact

Christoph Carstens

Sales Management

+49 (0) 4405 9888-18Callback service

christoph.carstens@kuro-kunststoffe.de

Imke zur Brügge

Sales manager pneumatic tubing

+49 (0) 4405 9888-22Callback service

imke.zurbruegge@kuro-kunststoffe.de