There is a solution for every pipe system problem: us here

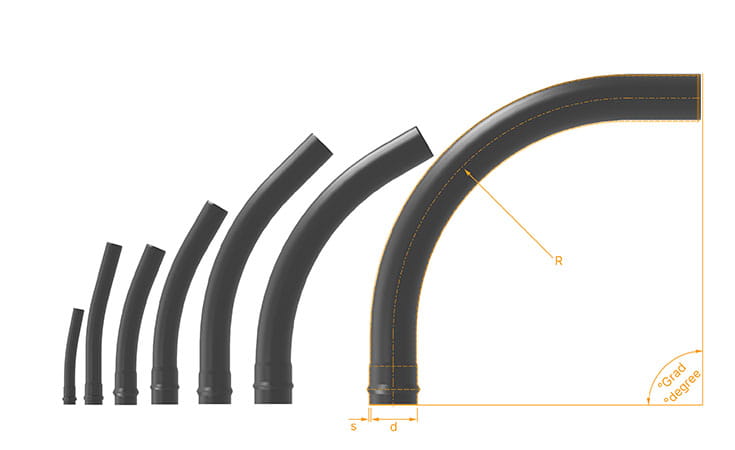

Customized bends

With innovative production processes and self-developed production processes, we have almost unlimited design possibilities for the Piping Bends - Tailored according to customer and product requirements. Molded pulps are produced in fully automated manufacturing processes, as well as in single-item production. There are almost no limits to the choice. In dimensions from DN 50 to DN 630, individual attention is paid to material, degree and radius. With over 30 years of experience, in-house toolmaking and more than 1100 bending tools, we are considered as a competent partner of the pipe industry.

Our solution for your need

Together with our team of experts, your bend project will be examined in detail for feasibility. The range of services includes:

- Diameter from DN 50 to DN 630

- Radius from 300 mm to 25.000 mm

- Degrees from 5° - 90°

- Materials PVC, PE-HD, PE-RT, PP, PP-RT, PC/ABS, PMMA etc.

- Pressed (seamless) or pulled

In addition to a meaningful offer, we individually design a 2D/3D drawing or further a sample for acceptance.

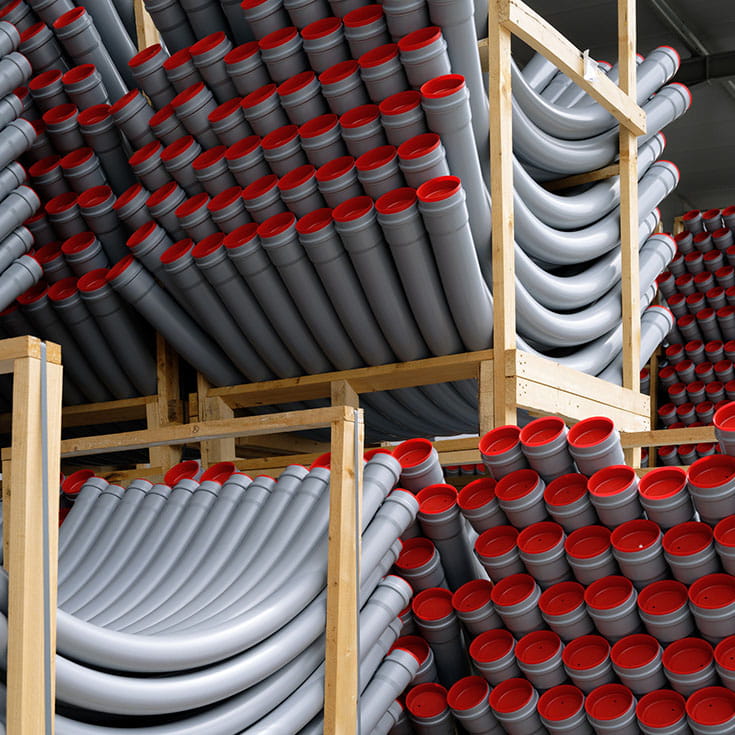

In addition to our in-house toolmaking, our tool inventory includes 1100 bending tools. This allows us to realize almost any requirement for your bend. From single-item production to series production or as contract manufacturing with the customer's own material, your bend will be manufactured accurately to the degree and with high precision.

A warehouse area of 10.000 sqm offers the possibility to optimally store blanks and finished products. Excellent logistics and packaging solutions enable delivery individually according to customer requirements.

Contact

Christoph Carstens

Sales Management

+49 (0) 4405 9888-18Callback service

christoph.carstens@kuro-kunststoffe.de

Imke zur Brügge

Sales manager pneumatic tubing

+49 (0) 4405 9888-22Callback service

imke.zurbruegge@kuro-kunststoffe.de